Leistungen

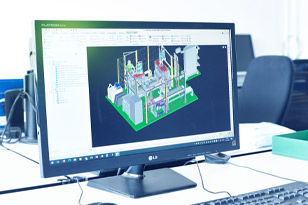

Engineering

Unsere erfahrenen Konstrukteure stehen Ihnen von Anfang an mit Fachwissen und aktuellster CAD-Technologie zur Seite.

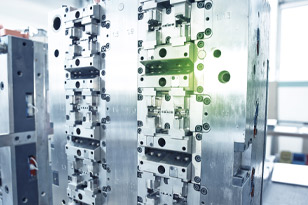

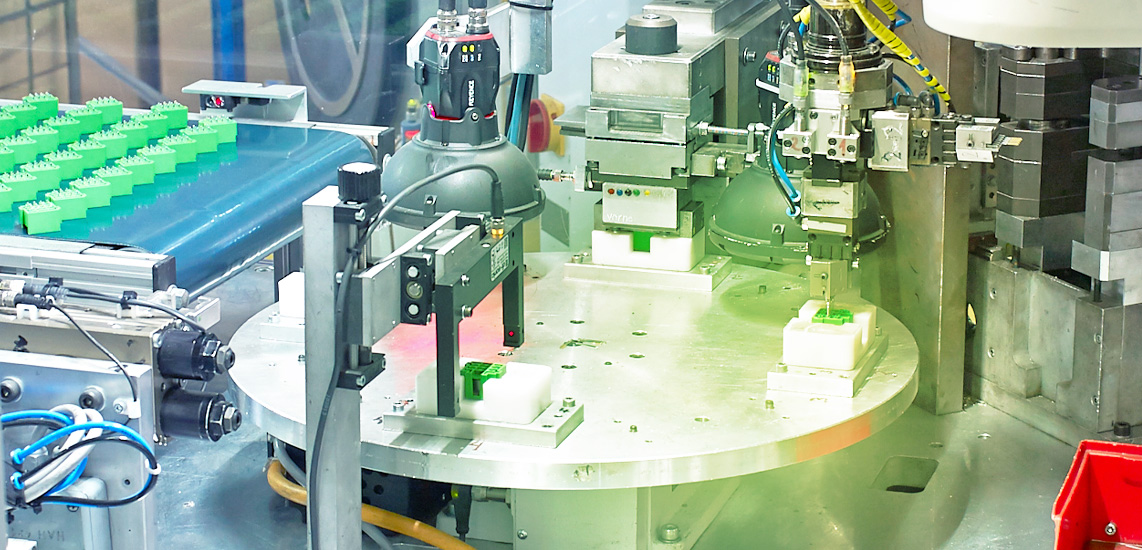

Produktion

Spritzguss auf über 60 Spritzgussmaschinen. Montage und Veredelung mit zahlreichen Automationslösungen.

Branchen

KWO ist zu Hause in den Branchen Automotive, Industrie, sowie Medizintechnik und Life Sciences. Eine teilweise jahrzehntelange Erfahrung in diesen Bereichen mit äußerst unterschiedlichen Anforderungen versetzen uns in die Lage, fast jeden Kundenwunsch umzusetzen.

01

Automobilindustrie

Viele namhafte Hersteller der Zulieferindustrie und OEMs vertrauen auf KWO.

02

Industriesektor

Wir erfüllen mit einem hohen Maß an Flexibilität vielfältige technische Anforderungen.

03

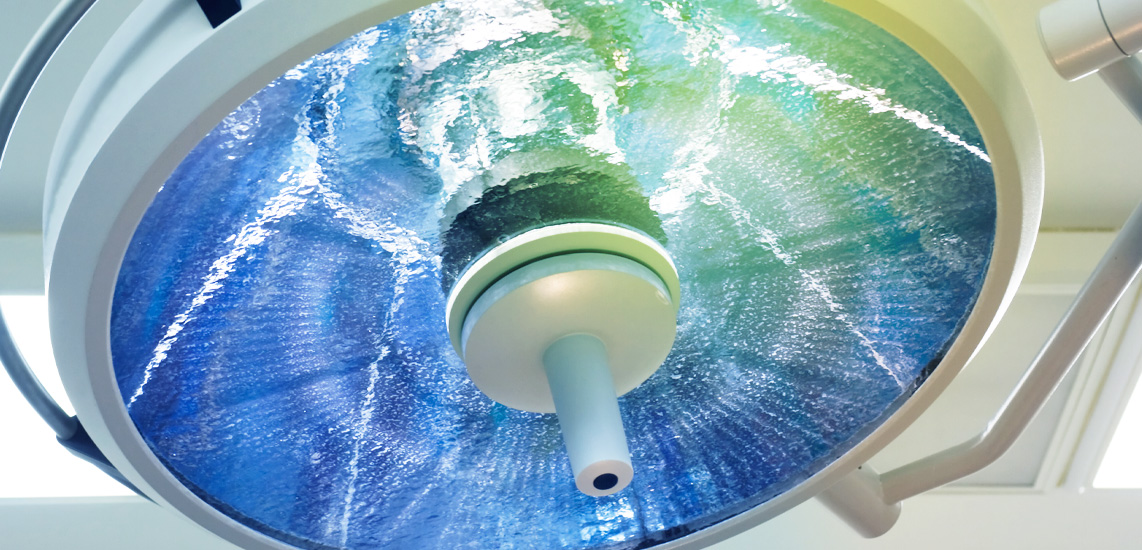

Medizintechnik / Life Science

Hohe Qualität, beste Materialien und Verarbeitung sind uns wichtig. Kunden schätzen dabei unsere Entwicklungsünterstützung

Zusammen stark.

Karriere bei KWO.

Wir suchen regelmäßig motivierte Mitarbeiter, die gemeinsam mit uns die weitere Zukunft von KWO in Offenau gestalten.

Als Ausbildungsbetrieb bieten wir jungen motivierten Menschen eine berufliche Perspektive.

Stellenangebote

Nehmen Sie Kontakt mit uns auf.

Anschrift

Talweg 9 + 13, 74254 Offenau

E-Mail Adresse

Telefon

+49 71 36 95 04-100